Aluminium Housings

Ideal for PCB, Eurocard and electronics installation

Guide Aluminium Housings

Index

Benefits of our aluminium enclosures

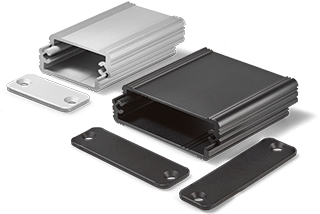

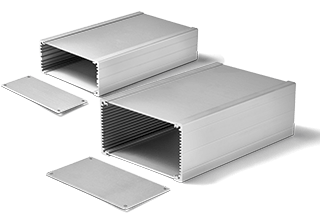

Our aluminium enclosures are designed to house electronic components. As electronic enclosures they are used for installation in electronics cabinets, as desktop or stand-alone enclosures or as remote controls for rugged handheld applications.

Our aluminium enclosures are manufactured by extrusion. An aluminium billet, heated to several hundred degrees, is pressed through a die to produce a profile several metres in length. The yard goods are then cut to the appropriate length for each enclosure. The aluminium profiles of the aluminium enclosures are designed to provide a wide range of enclosures for numerous applications. These include standardized aluminium enclosures to DIN IEC 61554:2002-08.

Aluminium enclosures are designed to achieve optimum IP ratings with appropriate sealing elements and provide effective protection against dust and moisture, ensuring that your electronic components and PCBs are optimally protected within an aluminium enclosure.

Aluminium alloys for hardness and strength

Aluminium is primarily a light metal and is quite soft in its pure form. By adding metals such as magnesium, silicon, manganese, zinc or copper, the material's properties are enhanced without noticeably changing its low weight. As a result, aluminium enclosures with the appropriate alloys are lightweight, corrosion resistant and robust components.

Our industrial enclosures are mainly made from the aluminium alloy AlMgSi0.5 (Al = Aluminium, Mg = Magnesium, Si = Silicon). The order of the symbols indicates the distribution of the metal masses with a silicon content of 0.5% (Si0.5). This aluminium alloy is resistant to corrosion and weathering, even in contact with seawater. The magnesium and silicon components also give the industrial housing greater hardness (high resistance to breakage and cracking) and strength (high flexural strength). The abbreviation "F" indicates the strength of the alloy, e.g. F22.

All of these properties make the enclosures easier to machine, making them ideal for milling, drilling and customization.

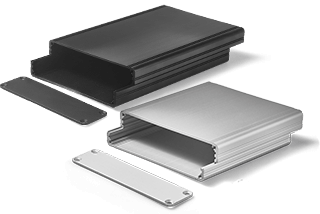

Anodized aluminium housing - electrically insulated

Anodizing gives aluminium enclosures a pleasant look and feel, protects them from the environment and, most importantly, provides electrical insulation with a dielectric strength of several hundred volts (typically 900V).

Raw or bare aluminium enclosures have 'only' a natural surface oxide layer of a few nanometres. This thin and transparent layer is not able to protect the enclosure permanently from harsh environmental conditions and corrosion. To give the raw aluminium enclosure a surface finish that is suitable for industrial use, the enclosures are anodized.

To prepare the surface for the anodizing process, the enclosures must be etched with suitable alkaline solutions, depending on the aluminium alloy. This removes the natural oxide layer. The surface is now porous enough to be coloured to the customer's requirements. The anodizing process that follows is an electrolytic process in an acid bath under direct current. This converts the top surface layer back into an oxide layer of several micrometres, depending on the process. The desired degree of surface hardness is then achieved by adding special additives in a water bath. This process also prevents any colour particles that may have been introduced from discolouring.

Product customizations

Custom designs are available on request. In addition to custom length enclosures, we can also carry out further processing such as drilling, punching or milling to dimensional drawings. We can also provide printing, chromating of bare enclosures, colouring to customer requirements, other materials and thicknesses and much more.

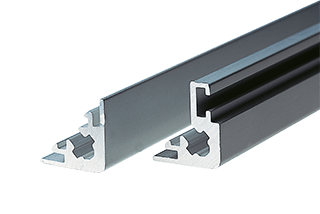

Aluminium enclosures from ELPAC powered by MEGATRON offer a wide range of aluminium profiles for enclosures in various sizes, lengths and shapes. The wide range of variants leaves hardly anything to be desired in terms of flexible design for PCB and Eurocard installation. The aluminium housings achieve optimum IP protection classes with corresponding sealing elements and are available for machine and plant construction and apparatus engineering.

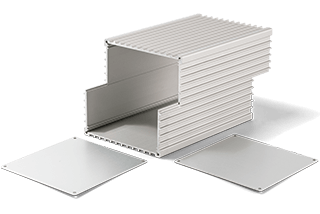

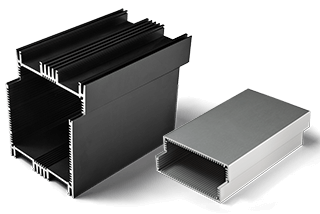

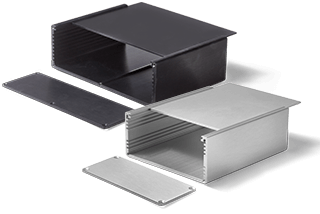

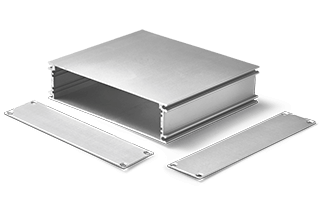

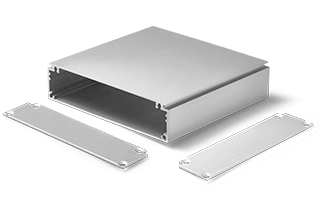

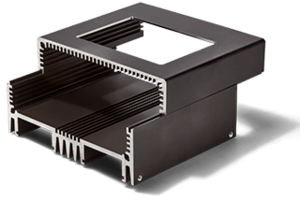

You have the choice between tongue and groove systems, housings with slide-in cover and full profile housings. Housings with cooling fins for optimized heat dissipation and in DIN formats for standardized use complete the range. The profile enclosures are supplied as kits for self-assembly and, depending on the version, consist of aluminium profiles, with cover or end plates (incl. mounting parts), if necessary with plastic frames and optional sealing elements.

We realize individual designs according to customer requirements on request. MEGATRON is your specialist for customized product adaptations. With high delivery reliability and assured quality products, we focus on long-term partnerships and accompany you throughout the entire lifespan of your application.

EN

EN DE

DE ES

ES FR

FR IT

IT