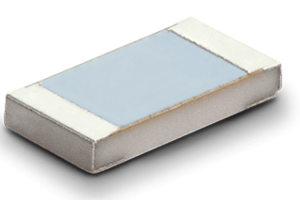

The conductive plastic potentiometers in the MHP24 and MHP32 series especially demonstrate their advantages in very confined spaces: thanks to direct mounting on the drive shaft, users are able to save setup time and costs. With the high-quality, multi-finger precious-metal wiper, a stable output signal is also achieved.

With a housing diameter of just 24 mm and a depth of a mere 7.1 mm, the MHP24 series from MEGATRON is ideal even for applications with very limited installation space. Since the hollow-shaft conductive plastic potentiometers do not require any coupling, not only is less space required, but the user also saves the costs of a shaft coupling and its installation. Integrating the MHP24 potentiometer is easy: it can be pushed with the flattened hollow shaft hub onto the shaft and is secured in place with an anti-rotation pin. The design principles eliminates any tension caused by axial shaft drift.

The MHP32 series with a diameter of 31.5 mm and depth of 8 mm is slightly larger, however it offers the advantage of backlash-free installation as it has a spring sheet in the hub. An anti-rotation fork is used to support the housing. Any backlash that can occur with the MHP24 due to the shaft flattening is therefore largely avoided with the MHP32. Both potentiometer series have an electrically effective angle of rotation of 340° and, thanks to the high-quality precious metal multi-finger wiper, deliver a stable analogue output signal.

Users are able to deploy the potentiometers in numerous areas of application, for example as angle sensors on robot arms or as position feedback sensors in engine valves and actuators. MEGATRON offers customer-specific modifications such as different angles of rotation, short circuit zones or resistance values as well as customized housing adaptations.

EN

EN DE

DE ES

ES FR

FR IT

IT