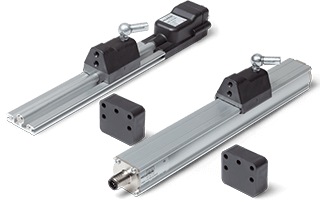

The robust MEGATRON linear sensors of the series OMS2 and PMS2 have outstanding EMC Interference immunity, a continuously high resolution and are resistant to shocks and vibrations. This makes them ideal for use in rough industrial environments with electromagnetic disruptions. Their magnetostrictive, contactless measuring principle ensures low-maintenance operations with no wear and tear and allows for a long service life. The compact, highly precise linear sensors can be integrated into the measurement systems of numerous industries – from the food industry through to robotics.

The magnetostrictive linear sensors of the series OMS2 allow for positioning in applications with measurement ranges of between 50 and 1500 millimetres, those of the series PMS2 of between 50 and 4000 millimetres. Linear motion is mechanically captured via a led or a free positioning device. Two or more positioning devices can be used in one linear sensor. The position of the magnetic sensor is output as a linear analogue signal and is an absolute value. Position feedback is also available immediately after switching on and off.

The free magnet sensor has a lateral and horizontal offset of up to ±2 mm. The magnet sensor with ball coupling balances out the vertical and horizontal offset. This simplifies integration into applications exposed to strong shocks or vibrations. The sensors are available in protection class IP67. The facts that no push rod is required and that the lateral profile is flat mean that they can also be integrated into flat confined spaces to save space. The robust linear sensors further have a high electromagnetic compatibility in accordance with the EMC Directive 2014/30/EU. They particularly offer benefits in the wood, ceramic, plastic and metal processing industries – so wherever faultless functionality is required in rough environments subject to shocks and vibrations.

The sensor's signal pick-up was optimised compared to its predecessor models by changing the construction of the recipient coil. Measurements are conducted using the shear wave process. In this, a short electrical pulse at light speed (299.792.458 m/s) is triggered in the measuring rod. The electric pulse creates a circular magnetic field around the waveguide. The movable permanent magnet is placed just above the measuring rod for position determination. The pulse magnet wave created encounters the magnetically right-angle field lines of the permanent magnet. The magnetic fields overlap and this creates a torsional-mechanical-elastic density wave (Wiedemann effect) in this area of the waveguide. The mechanical density wave moves to the signal converter at the speed of sound of 2850 metres per second, which then converts it to electrical signals (Faraday effect). The time required between the electrical pulse generated and the arrival of the density wave in the electronics is calculated and based on this the distance to the permanent magnet.

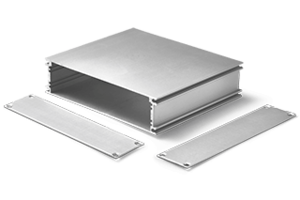

Megatron supplies contactless linear sensors in profile construction. These are suitable for universal use and can be installed directly on the structure to be measured with brackets. In addition, the electronics specialists at Putzbrunn also implement customer-specific product adjustments to the sensors.

EN

EN DE

DE ES

ES FR

FR IT

IT