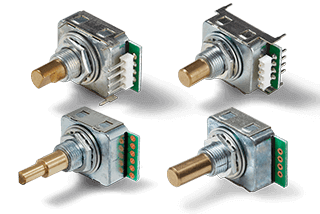

MEGATRON's MRB series of compact panel encoders offer a wide range of detents and tactile torques. Thanks to the numerous connection variants, the manual adjusters are suitable for a wide range of applications. Their attractive price structure also makes them interesting for price-sensitive devices.

MEGATRON's MRB series of manual adjusters fulfil the task of a human-machine interface (HMI). The sensors are characterized by their optoelectronic measuring principle, which ensures reliable and long-lasting operational safety. MRB series encoders have a long service life of at least 1 million shaft revolutions.

The manual encoders have a space-saving design and a high-quality feel. They are an alternative to mechanical encoders and are also available with an optional push-button. MEGATRON offers the MRB sensors in various versions: The solder pins can be oriented to the front, rear or bottom. The encoders can also be supplied with an optional flat ribbon cable, which can be customized by MEGATRON if required. A connector can also be fitted on request.

MEGATRON supplies MRB sensors with or without push-buttons and with 16 and 25 mechanical detents or without detents. Various detent and tactile torques are also available for optimum haptic properties. Thanks to their compact design and flexible mounting options, the MRB sensors can be easily integrated into a wide range of systems. In addition to the optional double shaft, MEGATRON also offers the matching rotary knob (OMT series) with integrated push-button for optimum setpoint input, including the option of activating user-specific modes.

MRB encoders offer a resolution of 25 or 16 pulses per revolution. Available with a 5V or 3.3V supply voltage, the encoders can be supplied with a shaft seal for increased IP protection. With a current consumption of less than 10 mA, they are particularly suitable for low power applications such as battery operation. A built-in TTL circuit with Schmitt trigger stabilizes input signal variations, ensuring a constant output signal.

EN

EN DE

DE ES

ES FR

FR IT

IT