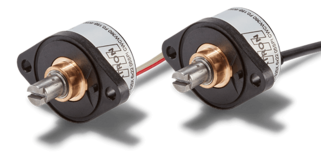

The ETx25 product family

- Encoder mounting M10 central thread

- Housing Ø25 mm

- Ø6 mm sleeve bearing shaft

- Electrical connection: solder contacts, plug, 0.15 m ribbon cable, 1 m round cable

- Encoder mounting 2 pieces M3 screws

- Housing Ø23.5 mm

- Ø6 mm sleeve bearing shaft

- Electrical connection: 0.15 m ribbon cable, 1 m round cable

- Encoder mounting 2 pieces M3 screws

- Housing Ø23.5 mm

- Without own shaft bearing

- Electrical connection: 0.15 m ribbon cable, 1 m round cable

The ETx25 encoders offer flexible, non-contact solutions for measuring angle, speed or position using precise Hall processors. These encoders are available in three housing styles:

- Solid shaft encoders (ETx25): For panel mounting, with standard Ø6 mm shaft and long life sleeve bearing.

- Flanged encoder (ETx25F): Also with standard Ø6 mm shaft and sleeve bearing.

- Kit encoder (ETx25K): For flange mounting on shafts with external bearing.

Materials and construction

- Shaft and bearing: Made from stainless steel for durability.

- Housing: Constructed from glass-fibre reinforced plastic for a robust and durable design.

Features and options

- Wide range of variants: Customizable designs to meet specific requirements, even customized variants are possible from small quantities.

- Durability: The sleeve bearing is designed for over 100 million revolutions and supports a continuous actuation speed of up to 100 rpm (up to 800 rpm for short periods).

- Signal outputs: Numerous options including analogue, incremental and digital outputs, including a programmable signal output function.

- Connection options: Up to four electrical connection options - solder, connector, ribbon cable or round cable.

- Operating temperature and protection: Suitable for a range of -40 to 80°C and up to IP66 on the shaft side, providing good protection against dust and splashing water.

This makes the ETx25 series versatile and adaptable, ideal for applications requiring high flexibility and durability in harsh environments.

EN

EN DE

DE ES

ES FR

FR IT

IT