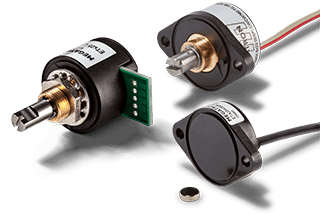

With the new ETx25K and ETx25F encoder series from MEGATRON, designers now have even more possibilities to integrate non-contact angle measurements into their applications. Both encoder series are characterized in particular by their convenient flange mounting, compact design, long lifespan and numerous electronic, mechanical and software options. The ETx25K is a kit encoder without shaft and shaft bearing, whereas the ETx25F is a shaft encoder with solid shaft and shaft bearing.

The two new series are even more compact than the previous ETx25 encoders. With a minimum installation depth of 8 mm (ETx25K) and 14.8 mm (ETx25F) and a housing diameter of 23.5 mm, the encoders can be optimally integrated into limited installation spaces. For convenient mounting, both encoder series are fixed with a flange (2 M3 screws). The ETx25K kit encoder has a mechanically unlimited lifespan. The ETx25F encoder is designed for over 100 million shaft revolutions thanks to its precision sleeve bearing. For the electrical connection, round or ribbon cables with axial cable outlet are available.

The ETx25K kit encoders do not have their own shaft with bearing and are designed for reliable angle measurement of external shafts with bearings. The actual sensor for measurement acquisition is located in the IP67 encapsulated encoder housing. For 3D Hall measurement, the external magnet included in the scope of delivery is attached to the shaft of the application. The encoder and the shaft of the application do not touch each other, so that the encoder can be mounted decoupled from vibrations and the thermal of the application and can reliably perform its service without mechanical limitations.

All encoders of the ETx25 family use a uniform sensor platform and are therefore available with analogue, incremental or digital output signals. In addition, all are available as single-turn encoders (measure angles up to 360°) and as encoders with a measuring range from 0...10° to 0...72000° for multi-turn tasks. The latter can even be programmed by the user himself. Customer-specific programming is available ex works for all encoders on request.

The functional principle of the ETx25 encoders is based on the contactless modern microprocessor-based 3D Hall technology, which gives the encoders their high reliability. They are available as absolute encoders with analogue output in 12-bit resolution, as serial angle encoders in 12-bit resolution with SSI or in 14-bit resolution with SPI interface, as rotary encoders with PWM output or as incremental encoders with up to 1024 pulses per revolution and the output signals TTL, push-pull or open collector. For function-critical applications, MEGATRON also offers encoders with two separate power supplies as well as electrically isolated outputs and redundant electronics.

The encoders of the ETx25 family are developed and manufactured in Germany. Thanks to their wide range of variants, hundreds of different combinations can be realized. Many options are also available as customer-specific solutions even for small quantities.

EN

EN DE

DE ES

ES FR

FR IT

IT