Multiturn Encoders

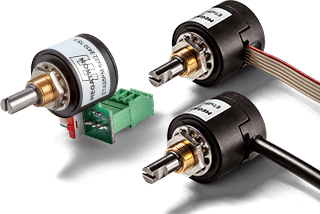

Magnetic multiturn encoders with analogue outputs for angular ranges up to 43 bit

Guide Multiturn Encoders

Index

What is a multiturn encoder?

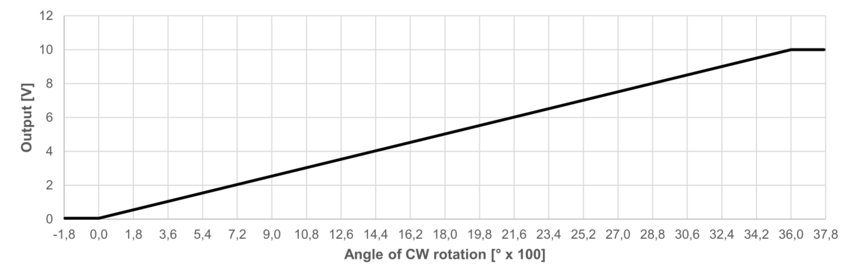

Most encoders that output angle information as an absolute value can only measure a maximum of one full shaft revolution, as the output value is repeated every 360°. However, it is often not sufficient to measure angle information for only one revolution. For example, if a mechanism takes several revolutions to reach the end of its range of motion, a sensor that can measure several revolutions is required. The sensor must be able to 'remember' how many revolutions it has already completed, so that the position of the mechanism within its setting path or setting angle is known to the control electronics. For these and other applications, only multiturn potentiometers have been available until now. A major advantage of programmable multiturn encoders is that the start and end positions can be programmed in the field in relation to the position of a mechanism. For example, the ETA25PM multi-turn encoder can be programmed up to 10,000 times, can measure angles up to 72,000° (200 shaft revolutions) and can also be used as a multi-programmable single-turn encoder.

Output signal from a multiturn encoder with a maximum angle of rotation of 36,000° (100 turns)

Basically, a distinction must be made between whether such an encoder loses its information about the angle of rotation when the supply voltage fails, or whether it can continue to detect rotation in a powerless state. This is discussed below.

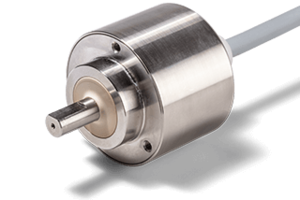

Magnetic multiturn encoders

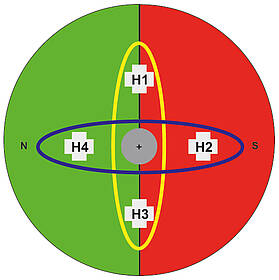

Many modern magnetic encoders use Hall sensors to measure angle. A magnet is placed over a sensor chip which measures the orientation of the magnet (see the Absolute Encoder Guide for details of the sensor technology). This can be achieved, for example, by using a singleturn encoder with extended functionality, which processes both the number of revolutions and the angular position. Another option is to use a reduction gear designed for a specific number of revolutions and use the electronics of a singleturn encoder to detect the angle.

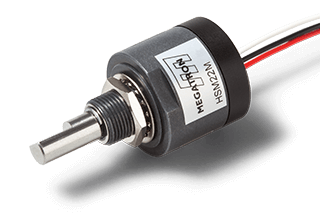

True-Power-On multiturn encoder

So that the information about the number of full revolutions and thus the correct angle information can be output exactly again after a power-off state, so-called "True Power On" multiturn encoders are used. This is guaranteed, for example, by the HSM22M series offered by MEGATRON.

This model offers the possibility of programming the voltage output according to customer-specific requirements. A simple method is to define the desired signal curve by means of interpolation points. Please contact us for more detailed information on the possibilities of this technology.

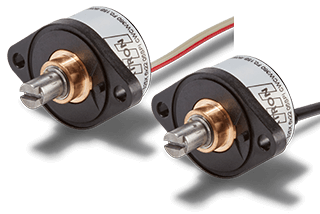

Multiturn encoders can measure angles over 360°. Our range includes absolute encoders with analogue outputs that can measure angles up to 43 bits. Some variants can be parameterized by the customer on site. This means that the electrically effective angle of rotation and the direction of rotation (CW / CCW) can be programmed in the field.

Multiturn encoders can, as the name suggests, measure several revolutions. So called "True-Power-On" multiturn encoders are used to ensure that the angular position can be measured exactly again when the shaft position changes after a voltage-free state. We offer multiturn encoders with gear as well as with volatile memory of the angular position.

Technical product adaptations are often required for demanding applications. MEGATRON is your specialist in such cases. As part of our consultancy service, we work with you to determine the optimum product for your "design in". With high delivery reliability and assured product quality, we focus on long-term partnerships and accompany you throughout the entire service life of your application.

EN

EN DE

DE ES

ES FR

FR IT

IT