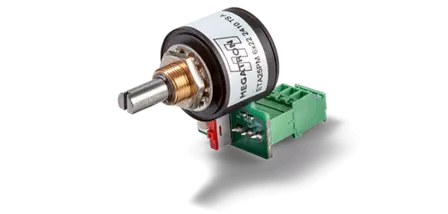

Product description: Hall effect encoders ETx25

ETx25 encoders are suitable for applications where long life and optimum adaptability of the sensor to the application are important.

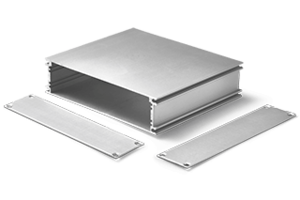

The ETx25 family of Hall-effect encoders is characterized by its high reliability as well as lifespan of over 100 million revolutions and an independent linearity of up to ±0.3%. The encoders detect angles without contact and have a highly hardened and tempered metal sleeve bearing. The sensor in Ø25 mm housing with Ø6 mm or 6.35 mm (1/4 ") shaft is fixed in the application by means of a central thread (AF14 hex nut and a tooth washer, both included in scope of delivery). A convenient choice of electrical connections is available using solder, clamp, round, flat or ribbon cable. The following electronics can be selected:

ETA25 singleturn absolute encoder (ETA25X redundant version):

Provides an absolute analogue signal with 12 bit resolution. For safety and critical applications, the ETA25X offers galvanically isolated and redundant electronics (see ETA25X series datasheet).

ETA25PM, Teach-In-Encoder, programmable multiturn or singleturn absolute encoder:

Field-Programmable (Teach-in)-Encoder for angles of rotation up to 72000° (200 revolutions), can also be used as a singleturn encoder with Teach-in. 12 bit resolution with current or voltage output. Teach-in can be performed on site using a simple programming circuit.

ETI25 singleturn incremental encoder:

With up to 1024 pulses / per revolution and availability of following output signals: TTL, Push-Pull or Open Collector

ETS25 serial singleturn angle encoder:

14 bit resolution with SPI interface, redundantly available for SPI (ETS25X series)

ETP25 PWM singleturn encoder:

With PWM output

The wide range of electronics variants for different voltage supplies and the variety of electrical interfaces for the output of measured values enable the ETx25 encoders to be optimally integrated into the application. The encoders can also be customized. Hundreds of possible combinations can be realized at short notice using the ordering matrices in the data sheets. Popular options include

- changes the sense of rotation from CW (clockwise) to CCW (counterclockwise),

- user-defined rotation angles

- a shaft seal for increased IP protection

- increased actuating torque to prevent unintentional adjustment due to vibration. Also provides a high quality feel when used as a setpoint adjuster

- optionally with mechanical stop for defined angular values, with or without detent position in middle position (for use as setpoint adjuster/panel encoder)

EN

EN DE

DE ES

ES FR

FR